The welder in your workplace controls the thicknesses and forms of metals you can solder. A 230V MIG welder gives you additional power to handle a broader range of projects, ideal for people who face a range of difficulties.

The Hobart Handler 190 and the Lincoln180 are two excellent options if this suits your shop’s requirements. They can work with anything from thin sheet metal to larger, more powerful stuff. Both are also spool gun ready and come from reputable suppliers.

Users have praised each unit for its straightforward, dependable functioning. These two units appear to be nearly equal when compared side by side. Their appearance is almost similar since the same manufacturer makes them.

Therefore, when choosing the welding material, first check the two welding tools carefully.

Fortunately, the information below shows the common differences between Hobart 190 and Lincoln 180. Despite having differences, the article also indicates their similarities.

It offers its features and is the most recommended welding tool among the two, including why it is preferred. Also, it shows the FAQs.

Contents

A quick comparison table between Hobart 190 and Lincoln 180

| Comparison | Hobart 190 | Lincoln 180 |

| Weight | Weighs 68 lbs. | Weighs 56 lbs. |

| Thickness | Thickness ranges between 5 to 16 inch | Thickness ranges from 5 to 16 inch |

| Output range | It goes from 25 amperes to 190 amperes. | It ranges from 30 amperes to 180 amperes. |

| Duty cycle | For 130 amperes, the duty cycle is 30% | For 130 amperes, the duty cycle is 30% |

| Input voltage | Requires input voltage of 230 voltage. | The input ranges are two, 208 voltages and 230 voltages. |

| Voltage control | Has seven positions | Has five positions |

| Wire feed speed | Ranges between 40 to 740 ipm | Ranges from 50 to 500 ipm |

| Warranty period | At least one year and a maximum of five years | At least one year and a maximum of three years. |

| amperage | Ranges from 25 to 190 amperes | Ranges from 30 to 180 amperes. |

Hobart 190 vs. Lincoln 180

- Weight

Looking at the specifications, you’ll note that Lincoln 180 is 12 pounds lighter than the Hobart Handler 190. That’s enough to make a difference. However, when you add a 10-pound spool of wire, the cannon, and the ground wire with clamp, both components become too hefty to carry around daily. Each of these welders will almost certainly require a trolley.

The Lincoln 180, on the other hand, is the lightest welder available.

- Thickness

Lincoln 190 is thicker than the Hobart handler 190. The Hobart thickness ranges from 5 to 6 inches, while the Lincoln 180 runs from 3 to 16 inches. Some people prefer using thicker welding equipment, while others prefer using a thinner one.

Depending on the thickness, choose welding equipment with the thickness that suits your work perfectly.

- Output range

For the Hobart 190, the power output range starts from 25 amperes to 190 amperes. But for Lincoln, the output range is slightly different. It ranges from 30 amperes to 180 amperes.

The best way to know the output range is to perform a lab test of both devices and compare them before choosing the one that suits your taste.

- Duty cycle

The duty cycle for the Hobart 190 welding device is almost similar. For 130 amperes, the duty cycle is approximately 30%. The duty cycle is for a voltage of 21.5. for the Lincoln 180, the duty cycle at 130 amperes is about 30 %.

- Input voltage

The innovative technology in the Lincoln 180 enables it to run on 208 voltages right out of the box. So, with the Lincoln 180, you may utilize either 208 Voltage or 230 Voltage. For some, the Lincoln 180 will be the best option due to the power source present in their shop.

The Handler 190, on the other hand, has seven voltage settings, giving the operator more control over the arc. In addition, the 190 offers superior wire speed control.

For what it’s good, the Lincoln 180 uses a 6900-watt generator. As per Hobart’s specifications, the Handler 190 needs a minimum of 7000 watts from the generator.

- Voltage control

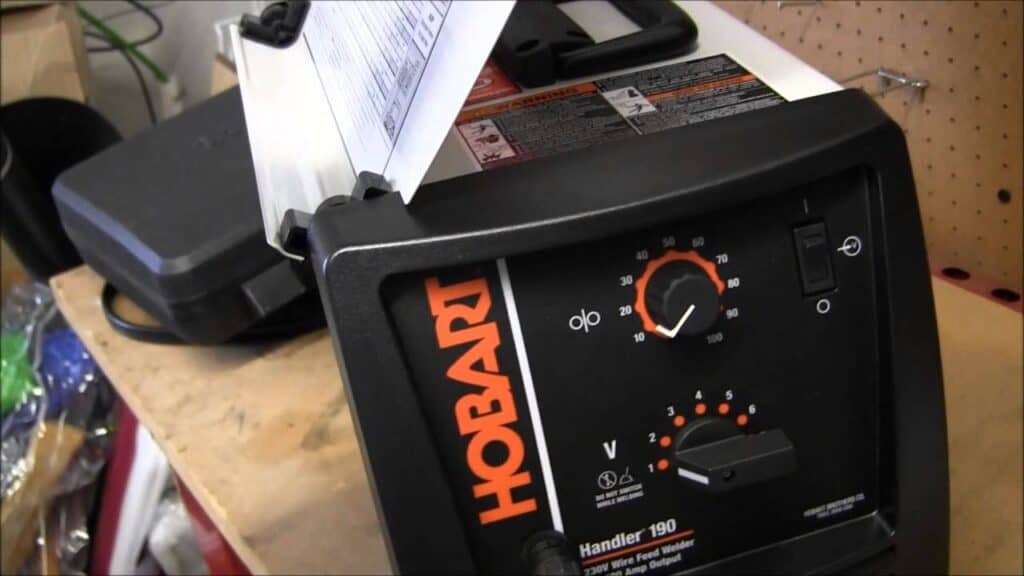

The Handler 190 has seven voltage settings, whereas the Lincoln 180 has five. Concerning thicker stock, the Handler 190 has an advantage over the Lincoln 180 because of its slightly higher current limit and seven choices. Both devices have an easy-to-understand control panel: two input knobs and a basic on/off lever.

The WFS is controlled by one dial, while the voltage adjustment is controlled by the other. The controls on both welders can operate with gloves on, although the knobs are thin. The additional electricity safety on the Handler 190 is restored with the on/off switch on the control panel.

The on/off switch on the Lincoln does not include this capability, and the additional safety reboot button is situated separately on the back of the unit. Except for position, there isn’t much variation between the controllers.

The Hobart 190 stacks the two dials vertically, whereas the Lincoln 180 places them side by side. Some people may prefer one over the other, but this is a slight distinction.

- Wire feed speed

With a wire-speed range of 40 ipm to 740 ipm, the Handler 190 outperforms the competition. The Lincoln 180 can feed wire at a rate of 50 ipm to 500 inches per minute. The Handler 190 is a wiser option if you need the most control over wire feed speed for projects that demand very slow or quick wire feed.

- Warranty period

The Lincoln 180 comes with a three-year guarantee, which is reasonable. The gun has a warranty of four months, and the gas regulator, which has a warranty of just a year, is the only exception. Hobart, on the other hand, gives a 1 to 5 warranty.

- Amperage

Each welder requires different amperage. The Lincoln 180 requires amperage between 30 to 18 amperes, whereas the Hobart 190 requires 25 to 190 amperes. The current requirements create a difference between the two welders.

Similarities between Hobart 190 and Lincoln 180

- Overheating prevention mechanism

Both machines have excessive heat prevention. Gas welding is difficult since the chemicals need replenishing regularly. Fortunately, all models come with a warning that explains how much gas you’ll require and how to set up the gas tank if you’re a novice.

- Fluxing equipment

Both the Hobart 190 and the Lincoln 180 have the necessary equipment for flux core and gas welding. When using gas with these devices, you don’t have to buy any equipment. Of course, you could also do standard metalwork. There aren’t any issues.

- Portability feature

The Hobart 190 is lightweight, around 66 pounds, while the Lincoln 180 will be 68 pounds. You may find it tough to move them along due to their weight. It is, nevertheless, distinct if you use a trolley.

If you want to reduce the weight of your project, split each component after finishing reconnecting them as needed. Alternatively, you may purchase a cart to transport this equipment in.

Pros of the Lincoln 180 to Hobart 190

- Lighter

- It is applicable with either 208V or 230V power.

- With the provided regulator, you can run Carbon dioxide.

- With a transformer, it’s a lot simpler to use.

- Inclusion of a better set of “extras†in the package.

Cons

- There are fewer voltage options.

- Wire feed speed has a smaller range.

- Warranty coverage is less generous.

Pros of the Hobart Handler 190 to Lincoln 180

- There are seven different voltage choices.

- Three grooved quick transition drive roller

- A more comprehensive range of wire feed speeds is available.

- Long-term guarantee

- In one pass, welds thicker mild steel and aluminum.

- An improved user guide

Cons

- Heavier

- It cannot function on 208 voltages.

- The regulator does not use carbon(IV)Oxide.

The most recommended between Hobart 190 and Lincoln 180

You’ll see a significant difference when you compare the two for the instructions you have on your welding output. The Hobart Handler 190 comes out on top. You have more output options. That reflects the wider variety of welding outputs.

Also, the wire feed speed has a broader range. When you’re fixing a wide range of parts and metallic thicknesses with a welder, you’ll get more completed with the Hobart 190 if you’re making metal box parts.

You might be interested to read also our another comprehensive article of:

Frequently asked question:

- How can I use the spool gun for both welding devices?

Both welders contain a spool gun. For aluminum wire welding, a spool gun performs better. This pistol may easily be connected to the computer and used in place of the standard gun.

Replacing the weapons does not necessitate the use of any extra option tools. Neither of these welders requires a converter to utilize the spool gun. The setup and operation are considerably more straightforward than they appear at first.

Conclusion

Choosing the best welding equipment is essential. Before making any plan of buying the device, read the review above.

Compare the two welding devices and pick one that suits your preferences perfectly. For instance, if you want to choose the machine with more amperage, consider using the Lincoln 180 over Hobart 190 machine.

Finally, consider some factors before buying any welding machine. For example, consider the cost, power requirements, thickness, among others.

Also, carry out some research on where you are planning to buy the device to ensure they offer genuine products. Also, ensure they have a warranty period to help you reduce the additional costs of purchasing another device.